Addressing Key Challenges in Factory Floor Maintenance

Common Cleaning Challenges in Industrial Environments

Cleaning factory floors presents real problems because of all those oil spills, metal bits flying around, and stubborn chemical leftovers that just won't budge with regular sweeping or mopping. According to research from the Ponemon Institute last year, poor cleaning habits actually end up costing factories about seven hundred forty thousand dollars each year through accidents at work and when production gets held up. And things get even worse because so many people find factory cleaning tough work. Nearly two thirds of maintenance supervisors say they have trouble keeping good cleaners on board due to the harsh conditions in industrial settings. Then there's the whole mess with getting cleaning supplies too. When supply chains break down, equipment sits idle for almost a quarter longer than normal waiting for parts and materials to arrive.

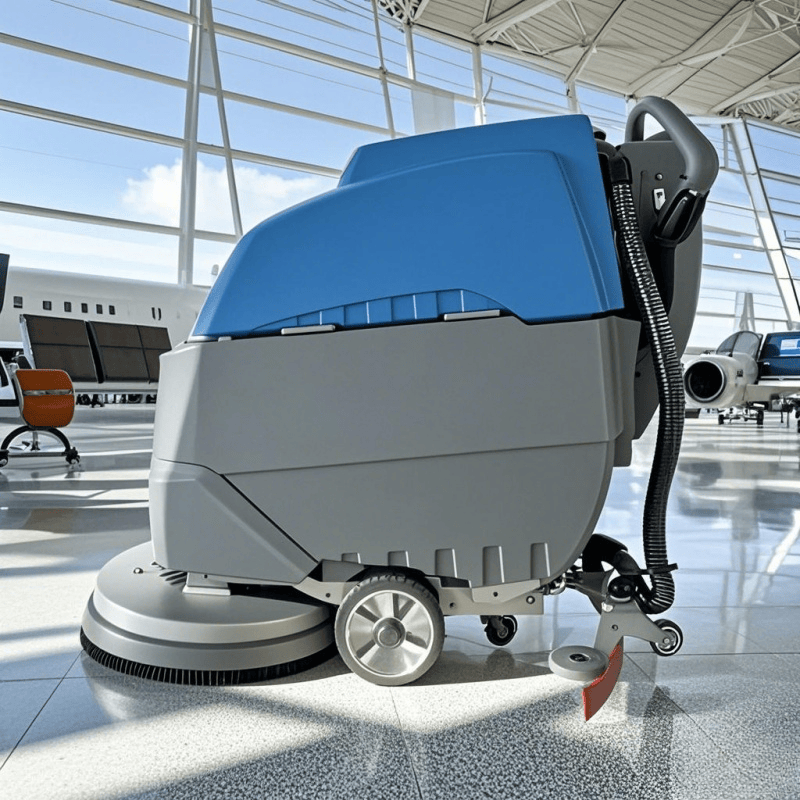

How Floor Washing Machines Meet Industrial Cleaning Demands

Today's floor washing tech tackles all sorts of cleaning issues thanks to those automatic scrubbing systems that knock out around 98% of dirt and grime particles with just one sweep across the floor. The powerful vacuum systems really make a difference too, cutting down leftover water on surfaces by about three quarters when compared to old school mopping methods, which means fewer accidents from slippery floors. For companies struggling to find enough staff, these machines are game changers. A single machine can do the work of anywhere between four to six people in big warehouses or factories, plus it keeps everything within OSHA safety guidelines for floor traction. Real world data shows places that switch to robotic scrubbers typically finish their cleaning tasks 40% quicker and use about 30% less cleaning chemicals because of those smart dispensing features. Industry reports back this up, but most facility managers will tell you they've seen these benefits firsthand after making the switch.

Automation and Efficiency in Industrial Cleaning Operations

Transition from Manual Labor to Automated Floor Washing Machines

The old way of cleaning factories used to need between four and six workers putting in full eight hour shifts, but now companies are switching to those self-driving floor washers that cut down on direct labor by almost 90%, according to research published by Steidl and colleagues back in 2023. What makes these machines so good is they take care of all those boring repetitive jobs nobody wants to do manually, stuff like scrubbing floors over and over again or mixing chemicals properly. At the same time, they keep applying steady pressure throughout their operation, hitting around 1200 pounds per square inch consistently. The water flow stays regulated too, working equally well whether it's on regular concrete floors, epoxy coated areas, or surfaces that have been sealed against spills.

Productivity Gains with Autonomous Scrubbers in Large Facilities

In large warehouses over 100,000 square feet, autonomous scrubbers can clean about 35% more space each hour compared to traditional manual cleaning teams. Warehouse managers report cutting down cleaning times by around 40% thanks to these machines' smart navigation systems that figure out the best routes around things like pallet racks and machinery on the floor. The newer battery powered versions typically last between 10 to 12 hours straight, which means less downtime for charging. They also use water pretty efficiently, somewhere between quarter to third of a gallon per minute during operation. This kind of performance makes them increasingly popular among facility managers looking to boost productivity while keeping costs under control.

Case Study: Automated Cleaning in a 50,000 Sq Ft Manufacturing Plant

An automotive parts factory in Ohio managed to save around $214k each year on floor maintenance after getting three robotic scrubbers running. These machines come equipped with smart sensors that pick up where people walk the most around those assembly line areas. During busy production hours, they actually bump up their cleaning schedule from just two times a day all the way to once every hour. The result? Slip accidents dropped by nearly three quarters at the facility. Plus, water usage went down quite a bit too about 28 thousand gallons less per month than what was needed when workers cleaned manually before.

Smart Technology Integration in Floor Washing Machines

These days, floor washing machines are getting smart thanks to AI and IoT technology changing how we clean big spaces. The machine learning stuff actually looks at where people walk around and what kind of dirt is on the floors, so it can tweak how hard it scrubs and how much soap gets used on the spot. Take this for instance: some systems cut down on water consumption about 30 percent in areas where not many folks pass through, yet still keep things clean enough. That kind of efficiency matters a lot now since businesses want greener operations but nobody wants to see dirty floors either.

Smart Sensors and Autonomous Navigation in Robotic Cleaners

Advanced models deploy Lidar mapping and inertial guidance systems to navigate complex factory layouts. These machines:

- Avoid obstacles using 360° proximity sensors

- Optimize routes to clean 15% faster than manual operators

- Self-dock for recharging when battery levels drop below 20%

This autonomous operation eliminates human exposure to hazardous areas and allows cleaning during off-shift hours.

Balancing High Initial Cost With Long-Term ROI of Smart Cleaning Systems

While smart floor washing machines require 40–60% higher upfront investment than traditional models, they deliver measurable long-term savings:

| Cost Factor | Manual System | Smart System |

|---|---|---|

| Annual labor costs | $52k | $18k |

| Chemical waste | 12% | 5% |

| Downtime incidents | 7/yr | 1/yr |

Plant managers report 18-month payback periods through reduced overtime and 92% fewer slip-related insurance claims (Industrial Safety Report 2023).

Design and Durability for Demanding Factory Use

Key Design Features of Floor Washing Machines for Large Industrial Spaces

Today's floor washers are built tough, featuring solid steel frames and those special polyurethane wheels that can handle pretty serious impacts, around 1500 pounds worth actually. Most models come with industrial strength scrub decks that measure somewhere between 20 to 30 inches across, paired with big water tanks holding anywhere from 60 to 100 gallons. These specs mean they can keep going without stopping for refills even in massive facilities covering over 100 thousand square feet. Another great thing is the adjustable brush pressure system, which lets operators dial in between 40 and 120 psi depending on what surface they're dealing with. Works well on everything from basic concrete floors to tougher epoxy coatings found in many manufacturing plants.

Durability and Performance Under Continuous Heavy-Duty Operation

Tests from independent sources indicate premium floor washers stay ready to go about 98% of the time even after running all day for 18 hours straight. This reliability comes down to things like those stainless steel squeegees that resist rust and motors built to handle over 8,000 service hours before needing attention. Looking at what's happening in the industry right now, there's some interesting findings too. The newer scrubber heads made with polyurethane actually stick around nearly three times longer compared to regular nylon ones when used in tough spots where floors get really worn down. And this means big savings for businesses since they spend roughly $2,100 less each year on replacing parts for every single machine they operate.

Battery-Powered and Energy-Efficient Operation in Practice

Advanced lithium-ion batteries now provide 6–8 hours of runtime—30% longer than lead-acid models—while cutting energy consumption by 19% compared to diesel-powered systems. Facilities using battery-driven floor washing machines report 42% lower monthly energy costs (average $380 savings for 50,000 sq ft plants), with fast-charging capabilities (1.5 hours for full charge) minimizing downtime between shifts.

Improving Workplace Safety and Operational Economics

Reducing Slip Hazards and Contamination Through Consistent Cleaning

Keeping floors clean in busy workspaces helps prevent slips and falls, which is where floor washing machines come in handy. According to recent research from 2024 looking at industrial safety, workplaces that switched to automatic cleaning saw about 62 percent fewer slip accidents than those still relying on hand cleaning methods (source: Adem study). The machines tackle all sorts of messes - think oil spills, leftover coolants, and dust accumulation - by running regular deep cleaning sessions throughout the day. This approach gets rid of contaminants before they become a problem instead of just sweeping them under the rug so to speak.

Compliance With Health and Safety Regulations Using Automated Systems

Modern floor scrubbers simplify adherence to OSHA and EPA standards with built-in compliance features. According to a 2023 manufacturing safety analysis, facilities using intelligent systems achieved 98% audit compliance versus 74% with traditional methods. Automated water usage tracking and chemical dispensing ensure accurate record-keeping, critical for hazardous material reporting.

Labor Savings, Reduced Downtime, and Cost-Benefit Analysis

Floor washing machines cut down on staffing expenses significantly compared to traditional mopping crews, saving around $18 each hour per worker plus they work about three times quicker. According to facility managers, downtime costs have dropped by roughly forty percent because these machines keep cleaning without stopping production (as noted in Ghobakhloo's research from 2020). Most businesses see their return on investment within just fourteen months when they switch to commercial quality systems. This happens mainly because there are fewer workplace injuries reported and insurance rates tend to go down too.

FAQ

Why is cleaning factory floors challenging?

Factory floors often have oil spills, metal debris, and chemical residues that are difficult to clean with traditional methods.

How do floor washing machines meet industrial demands?

They use automatic scrubbing systems and powerful vacuums to remove dirt, reduce water usage, and improve safety and efficiency.

What are the benefits of using autonomous scrubbers?

These machines increase productivity, reduce labor costs, and enhance safety by minimizing manual cleaning efforts.

Do smart floor washing machines offer a good ROI?

Yes, despite a higher upfront cost, they provide long-term savings by reducing labor, chemical waste, and downtime.

How do these machines improve workplace safety?

By maintaining clean floors, they reduce slip hazards and ensure compliance with health and safety regulations.